描述

Nicko’s 3 Function planetary mixer 100L

1.Feature:

1.Molded by patent technology, four variable speeds can be changed among them without stopping the machine, and covers much larger scale which caters to more requirement of procedure of the processing;

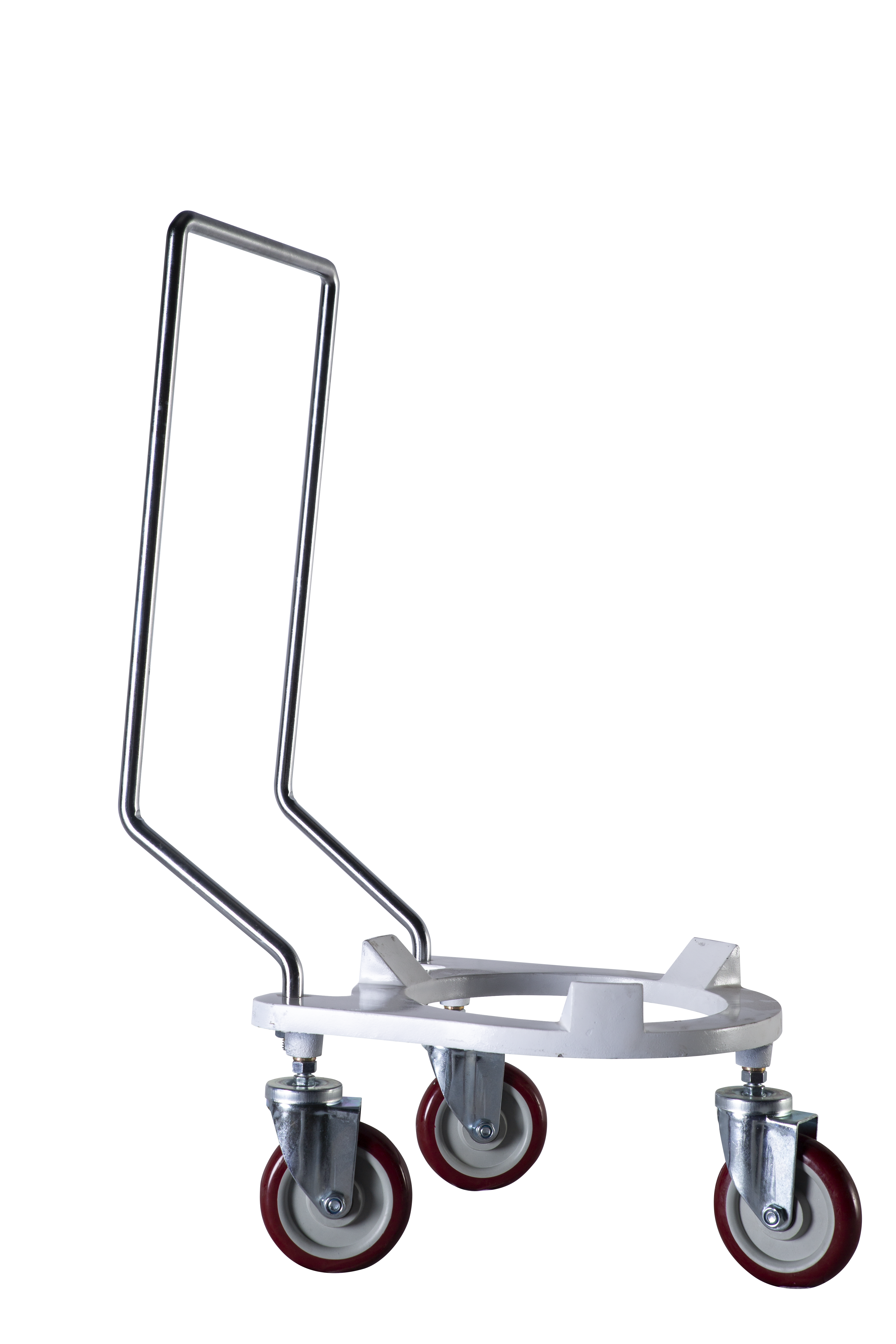

2.Four speeds shaft at random with blending timing function featured in the advanced motor controlling technology. Motorized up or down lift system of the bowl, the blender and the bowl can be moved without remove the ball. The cart can easily. move the bowl

3.Using gates belt and the gear adopt the material of car gear box and heat treatment procedure, the ability of wear resistance, rigidity ,toughness etc are above the same industrial level .

4.The material steel wire is stainless spring with high quality and good elasticity which makes the flat and the whisk fixed and durability

5.The machines are used to blend the stuffs of cake、cream、stuffing and flour etc. especially for making the liquid raw materials such as cake、yolk with a flexible、high density 、maximum output. The high productivity enable the machines extensively used by food factory、hotel、bread shop.

IMPORTANT SAFEGUARDS

1.Please read all the instructions carefully before use and retain for future reference;

2.To protect against risk of electrical show, do not immerse the appliance, cord or plug in water or other liquid;

3.Do not let children near appliance when the appliance is used;

4.Do not let finger near the running parts;

5.To protect against risk of electrical show to fir or injury, do not use the attachment which of not sold by us;

6.Unplug the appliance when not in use before cleaning;

7.Do not over the max contain of the appliance;

8.If power cord is damaged; to avoid danger, it must be replaced by manufactory or maintenance department or similar professional.

HOW TO INSTALL

1.Put the machine on a horizontal ground, adjust the adjustable foot so as make the machine stable and horizontal;

2.The power adopt three phase with four line system, the power wire must be linked with the machine to pull through the breaker, and the machine body grounded reliability ;

3.When the power on, take out the whisk or other spare parts, then test the machine;

4.Press the switch button on the operation panel and the indicator is lighting;

5.Press the speed buttons from speed 1 to speed 5 accordingly, if speed 1 and speed 2 run faster than speed 3 and speed 4, that shows that the phase sequence are wrong and the power wires are wrong connected, so any two wires should be changed. If the speed 1< speed 2<speed 3 <speed 4, that shows the power wires are connected correctly.

6.Press the barrel up or down buttons to test the barrel lifting system, pay attention to the spacing, whether the barrel up or down;

7.The spacing is invalid when the power wires are wrong connected;

8.The machine body will be destroyed if the barrel travels beyond the spacing, please avoid it surely;

9.Link with the whisk (flat or hook), if the barrel bump with the blender when testing , shows the height of the barrel support should be adjusted.

HOW TO USE

1.Make the barrel stay at the lowest position, and install the blender, then rise the barrel to a suitable height, turn on the switch and select the prompt speed to make the machine start working;

2.Put the stuff into the barrel according to the appointed height , then locate and fasten the barrel;

3.The blenders are :

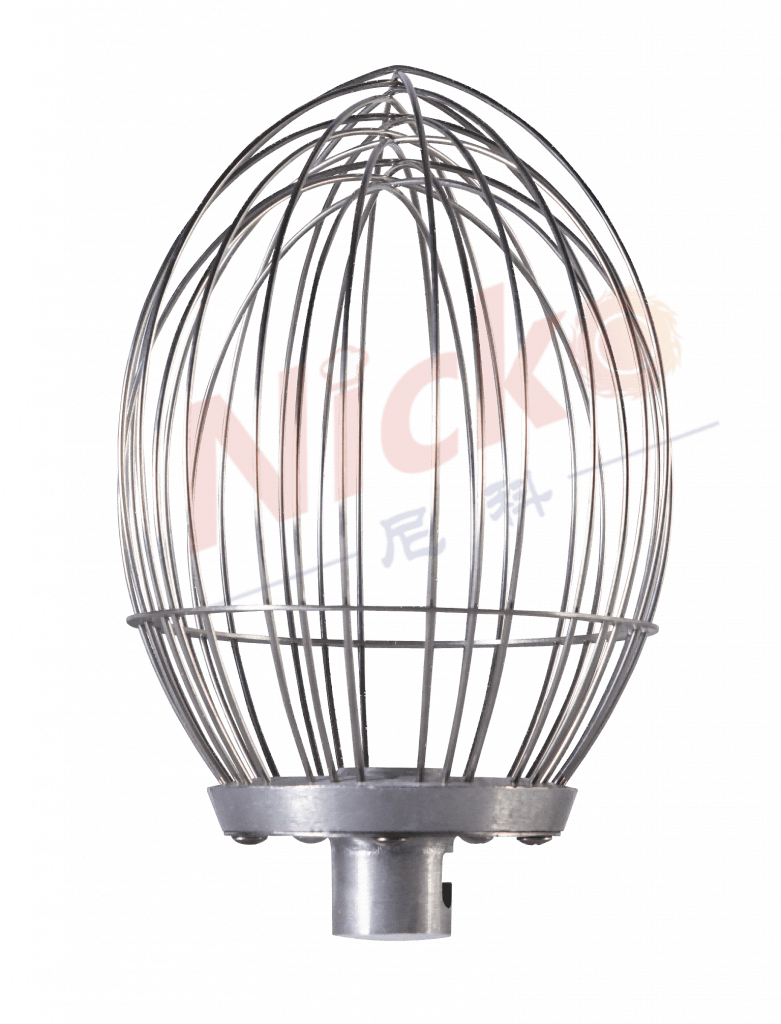

Whisk ball:

for blending liquid yolk、cream

Flat :

for blending the stuff of biscuit、cake and the speed 1 or speed 2 are best choice;

Hook:

for dough flour of bread、biscuit、pizza etc. Speed 1 or speed 2 is used;

4.Press the down button of the barrel to make the barrel down to the bottom then remove it.

HOW TO CLEAN

1.Be sure to unplug from outlet before cleaning

2.Immerse the foods plate & dough hook and beaters in water for clean-out, (Never to scrub the appliance with metal-ball)

3.Wipes clean the motor housing and the base with a damp cloth, never immerse in the water.

MAINTENANCE

.The machine belongs to food machine, it should be power off and clear the face of the machine after use;

2.The parts should be taken down which touch with the foods and clear it after using every day to ensure the hygiene;

3.Clear out the oil stain stayed on the guide way, add a little lubricate oil enable it to move freely;

4.Check the gear box periodically, add or change the lubricate oil when need.

NOTICES !

- Grounding the machine to be reliable in order to avoid the possible risk of electric shock

- Grounding should not be linked with the gas pipes, water pipes ,telephone lines and lightning ,after the installation of power ,please check for leakage ;

- Before washing the machine ,pull out of the plug, and the wash it by soft micro-cleaning cloth ,not directly used in liquid or spray –cleaning agent ;

- Encountered the following, please unplug power plugs ,to be follows by professional help :

- Power lines, power sockets wear or damage

- Liquid spilled over the machine , or water –soaked machine

- Machine has been dropped or damage shell

- Operated by the operation manual ,but machine still not normal works

- Machine performance suddenly changes

5.Please read the instruction manual before testing, to connect the power source by professional electrician so as to ensure the phase sequence in good order, that is speed 1< speed 2 <speed 3 <speed 4, press the upward button ,the barrel support rises ,or down when pressing the downward button;

6、The machine body must be grounded with copper wire which the diameter is more than 2.5mm2; the grounded resistance is not less than 0.1Ω;

- The machine must be stopped when take out the stuff from the barrel

8.When install or take down the blender ,should stop the machine, the machine should be power OFF when maintenance、clearing or moving

2.The usage of mixer and advantage:

Hook: For mixing bread, dough, pizza, ect. Hook with a spiral design, the machine running continuously on the dough, flip squeeze under. Make the dough toughness, fully excavated, making pasta and flexible, and good taste.

Ball: For processing cream, cakes, salads, egg. Sphere steel imported 304 stainless steel wire, with good rigidity and toughness. Mixing fast, small and rich bubbles, the amount of bubbles to pass more delicate egg. After the finished cake of the mouth soft, good stiffness, moisture resistance, is the most suitable raw material stirring cake embryo.

Bat: For the sauce, stuffing, candy. Stir article has stirred, without destroying the original flavor of food functions, saving time and effort.

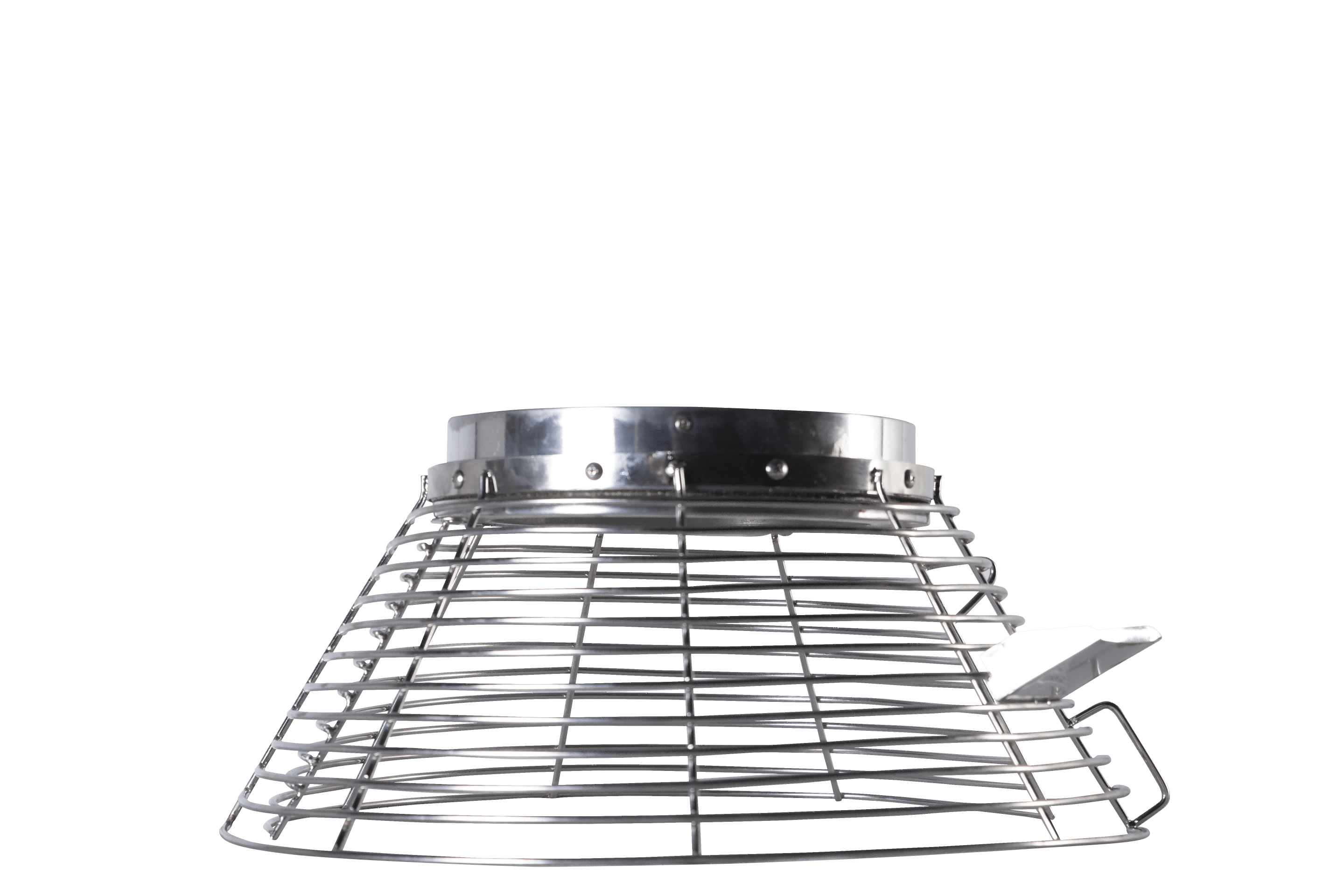

Other ancillary products:

|  |  |

3 Function Planetary mixer Parameter

| Type | Voltage 3 Phases | Power (KW) | Mixing speed(r/min) | Bowl capacity(L) | Weight (kg) | External Dimensions(MM) |

| NKB-60 | 380V | 2.8 | 86/127/228/337 | 60 | 350 | 956*624*1450 |

| NKB-80 | 380V | 4.0 | 86/127/228/337 | 80 | 430 | 1074*680*1600 |

| NKB-100 | 380V | 5.5 | 76/115/204/306 | 100 | 480 | 1120*760*1750 |

4. How to using the agitator

| Products suitable for planetarymixer | Agitator Suitable for operation | ||

| Wire Whip(third speed) | Flat Beate(second speed) | Dough Hook(first speed) | |

| Meringue | √ | ||

| Egg Whites | √ | ||

| Whipped Cream | √ | ||

| Mayonnaise | √ | ||

| Waffle or Hot cake | √ | √ | |

| Cake Cup | √ | √ | |

| Cake layer | √ | √ | |

| Cake Short(Sponge) | √ | √ | |

| Cookies Suger | √ | ||

| Mashed Potatoes | √ | ||

| Dough thin Pizza 40%AR | √ | ||

| Dough Med Pizza 50% | √ | ||

| Dough Heavy Bread 55% | √ | ||

| Dough Whole Wheat 70% | √ | ||

| Dough Raised Dounut 65% | √ | ||

| Dough Thick Pizza 60% | √ | ||

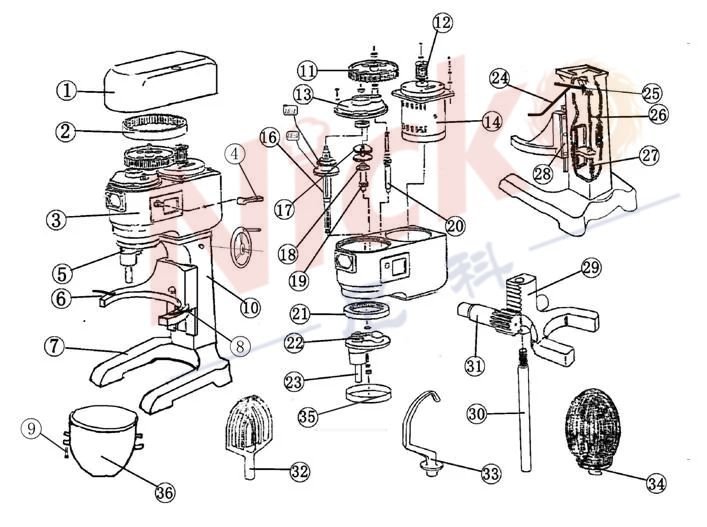

5. Nicko’s 3 Function planetary mixer 60L Product illustration

6.Nicko’s 3 Function planetary mixer 100L Product details display

| NO. | Name of the spare parts | NO. | Name of the spare parts |

| 1 | Cover | 21 | Annular gear |

| 2 | Belt | 22 | Torticollis gear wheel |

| 3 | Nose | 23 | Torticollis axis |

| 4 | Gear Change hand lever | 24 | Rocker |

| 5 | Torticollis | 25 | Small bird head |

| 6 | Bull angle | 26 | Pull rod |

| 7 | Pedestal | 27 | Pull rod spring |

| 8 | Switch | 28 | Guide way sizing |

| 9 | White iron ring | 29 | Shifting fork |

| 10 | Stand pillar | 30 | Tricolpate axis |

| 11 | Big belt wheel | 31 | Gear change |

| 12 | Motor belt wheel | 32 | Beater |

| 13 | Gear wheel cover | 33 | Hook |

| 14 | Motor | 34 | Whip |

| 15 | Triad gear | 35 | B axis thimble |

| 16 | Main axis | 36 | Bowl |

| 17 | B axis big gear wheel | 37 | Shield |

| 18 | B axis small gear wheel | 38 | On-off switch |

| 19 | B axis | 39 | Emergency switch |

| 20 | A axis | 40 | Limit switch |

As one of the key food machine enterprises in Guangzhou, China, Guangzhou Nicko Machinery Co., Ltd is specializes in the manufacture and export of food machine, kitchen equipment, bakery equipment, catering accessories and home appliances, etc.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in food processing industry and other industries. We are duly quality tested on the basis of their function, durability, efficiency and accuracy. These products are fabricated by using high grade quality raw materials and components that are sourced from the most trusted manufacture of the market. Our products are widely appreciated for their easy installation and help in many bakery applications.

Manufacturer information

Guangzhou Nicko Machinery Co., Ltd. was established in 2014 with a registered capital of 1 million yuan. It is a baking equipment enterprise integrating R&D, production, sales and service. The company introduces various advanced production equipment, such as laser cutting machines, NC bending machinists, and equipped with senior engineering designers and excellent technical production teams, to provide bakeries, pastry chains coffee shops, food factories, supermarkets, etc. with a complete set of baking production machinery for bread, cakes, and pastries. Such as Bread oven, rotary oven, tunnel oven, fermentation tank, dough mixer, etc. Our company’s business philosophy is “Only by stepping into the track of international standards, can there be unlimited space for extension ‘and adhering to the belief that “there is quality to have a market, and improvement to make progress”, with integrity management and the pursuit of excellence as the corporate purpose. On the basis of nearly two decades of experience in the research and development and manufacturing of baking equipment, we have made continuous technological improvements to various products, and will strive to provide every baking colleague with better baking equipment as our goal.

Professional production equipment

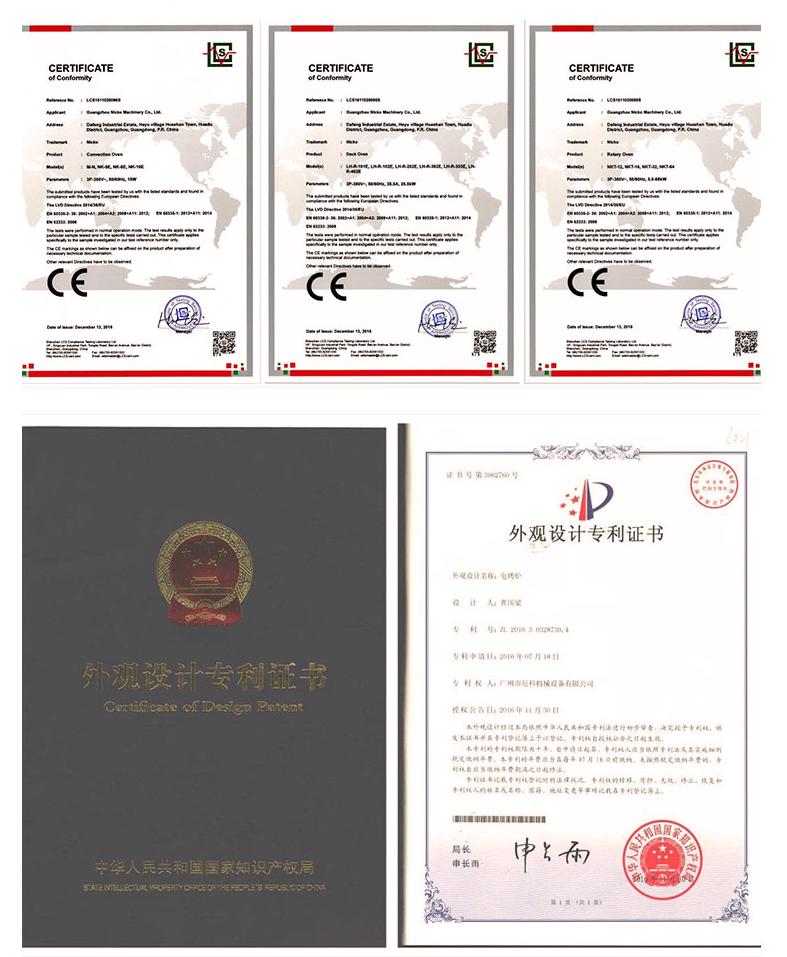

Enterprise certificates