If you have a small bakery, a combination oven may be all you need. But if you are running a large food processing plant or bakery, then a combination oven may not be enough. Now, you need to consider owning a particularly large industrial oven – a tunnel oven.

From the perspective of oven structure, tunnel ovens are very different from ordinary ovens. There is a conveyor belt inside so that products can run along the tunnel. It uses hot air circulation and temperature control to bake bread and biscuits fully and evenly through the heating device, and discharge moisture. With this large-scale equipment, you can quickly and mass-produce bread and biscuits, etc., which can reduce the production cost of bread and biscuits and increase the profit margin of your factory.

However, the cost of purchasing an industrial tunnel oven is not low, and its quality level is directly related to the quality of your food, so you need a complete and professional purchasing guide to find the baking equipment you need most, reduce risks, and make your Be successful in your career.

What factors need to be considered when choosing an industrial tunnel oven?

1.Production capacity

One thing that is clear is that if you have a large food factory, a tunnel oven is undoubtedly your first choice. But since each food factory has different production capacity and site area, how to choose the size of the tunnel oven? I can’t tell you the only answer, but choose based on your production needs and product size.

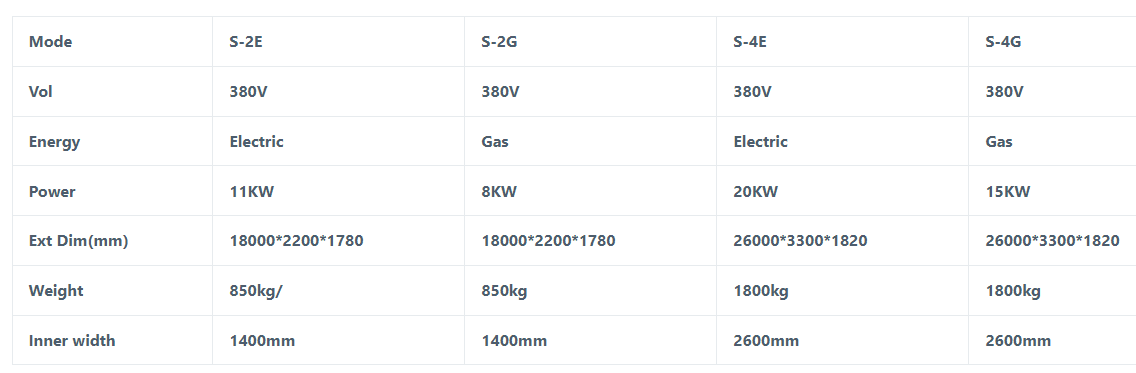

Take the popular Nicko tunnel oven currently on the market as an example. Its size data are as follows:

As can be seen from the picture above, Nicko’s industrial tunnel ovens come in four models, with different power, weight, Vol, capacity and heating methods. In addition, the tunnel-type design of its industrial tunnel furnace can easily automate and streamline production, saving time.

2.Heating method

Tunnel ovens usually have two heating methods, which can use electric heaters, gas burners, etc. The difference between an electric oven and a gas oven is obvious: the temperature control of an electric oven is more precise, and the heating speed is faster and safer; while a gas oven may not be so precise, and the burning speed is affected by multiple factors, but its cost is more Lower.

Distinguished by heating methods, Nicko has two types: electric ovens and gas ovens. Their energy consumption and costs are different. You can choose by yourself or consult Nicko’s sales staff, who will give professional answers.

3.Temperature control capability

For baking bread, its product quality has a lot to do with the accuracy of temperature control. Therefore, when you buy a tunnel oven, you need to know whether it has an accurate temperature control system and can provide even heat distribution to ensure consistent baking results for the product.

Nicko’s ovens use advanced electric heating technology and sophisticated temperature control systems to provide uniform temperature and humidity for your baked goods, resulting in better taste and higher quality.

4.Transportation system

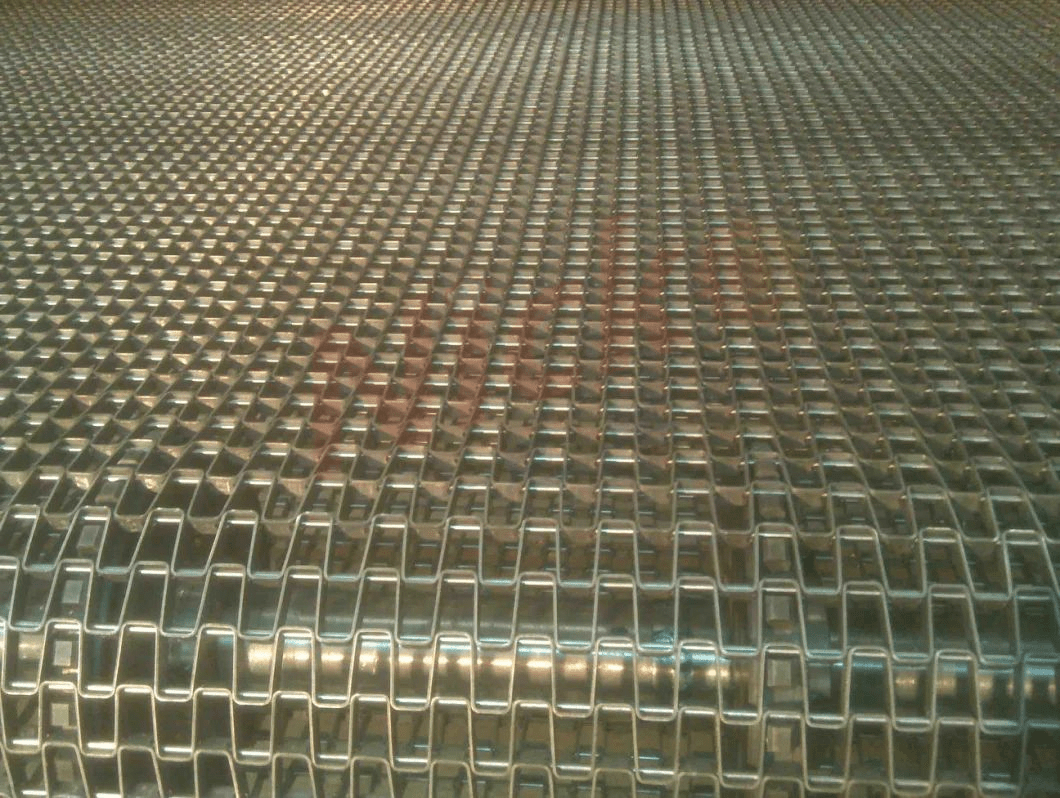

Consider product transportation systems for tunnel ovens, including conveyor belts or other transportation methods. Make sure the transport system can accommodate the size and shape of your product and provide the required efficiency.

Stainless steel 304 conveyor belt

5. Easy to maintain and clean

Because it is used frequently, a tunnel oven requires regular maintenance and cleaning. Therefore, you need to choose equipment that is reliable and easy to maintain to ensure the stability of the production process.

For example, Nicko’s tunnel oven is made of high-quality stainless steel inside, which is extremely difficult to corrode and easier to clean and maintain, allowing you to focus more on the baking process without worrying about oven cleaning, reducing a lot of maintenance costs.

6.Safety protection device

Safety is an important part of industrial production. We should protect the safety and health of every worker, so it is very important to ensure the safety facilities of the tunnel oven, such as temperature protection devices, fire alarm systems and emergency shutdown devices. Take Nicko’s tunnel oven as an example. It is understood that it has multiple protection measures such as overheating protection and leakage protection to provide a safer operating environment.

7.Manufacturer reputation

Excellent equipment is highly related to the production philosophy and credibility of its manufacturer. We all know that it is very important to choose a reputable tunnel oven manufacturer. In addition to referring to pre-sales consultation, after-sales support and repair service policies, you can also check its intellectual property patent certificate, which is more credible.