Croissant is a fluffy bread that everyone is familiar with. Its crispy texture and rich milky aroma are impressive. At breakfast and afternoon tea, the combination of coffee and croissant can be said to be both delicious and elegant, making people feel the beauty of life.

The history of croissants can be traced back to 2,000 years ago, originating from the crescent-shaped cakes used in religious ceremonies by the Persians, Greeks and others. Later, this type of bread appearance developed into Western Europe. In the 1920s, French pastry croissants made of butter were sold in France, becoming a representative of French style and a symbol of French cuisine.

As European culture spreads throughout the world, croissants are becoming more and more popular. Especially the croissant’s attractive golden pastry, crispy texture and milky flavor are impressive. Therefore, croissants almost appear in most food windows, with huge sales. This also allows many bakeries and food manufacturers to produce croissant bread, which brings huge profits.

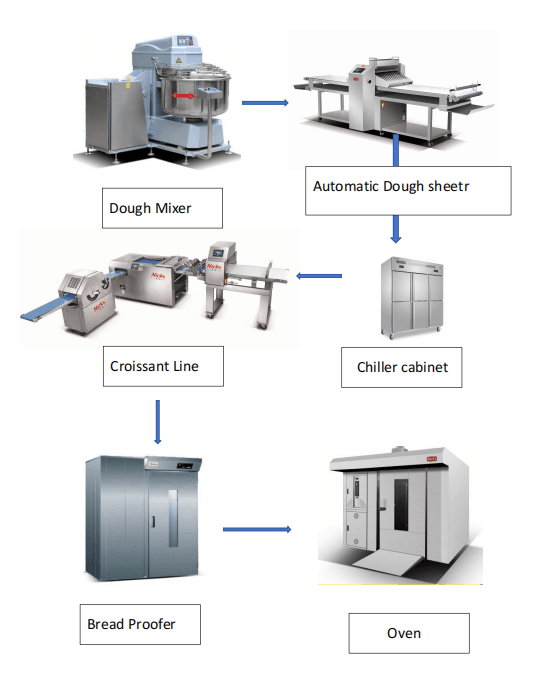

The following takes Nicko, a professional baking equipment manufacturer, as an example to list a complete croissant production line purchase list, including the functions of each product, to help you produce more and better croissants.

Complete equipment list for Nicko croissant production line

As the world’s most professional baking manufacturer, nicko provides croissant lines with complete equipment, including 800Z automatic dough sheeting machine, JP-630 average dough leveling machine, NK600 sharpening machine, CJ200 croissant line, P600 automatic conveyor, The T-64G gas-fired rotary oven has a high degree of automation, fast production speed, reliable quality and longer service life. It has been purchased by a large number of customers around the world.

In addition, Nicko is also a one-stop manufacturer of complete baking equipment. It also provides dough mixers, automatic dough slicers, cold water cabinets, bread proofing machines and professional ovens. Together with the croissant production line, Nicko forms a complete croissant production line and equipment. Complete, highly automated equipment, seamless processes, and high production efficiency.

Introduction to various equipment of croissant production line

If you run a bakery or food factory, then you need to fully understand the purpose of different equipment before purchasing professional croissant making equipment. After purchasing these equipment, in addition to reading the product manual in detail and consulting the sales manager, you can also have a preliminary understanding of them.

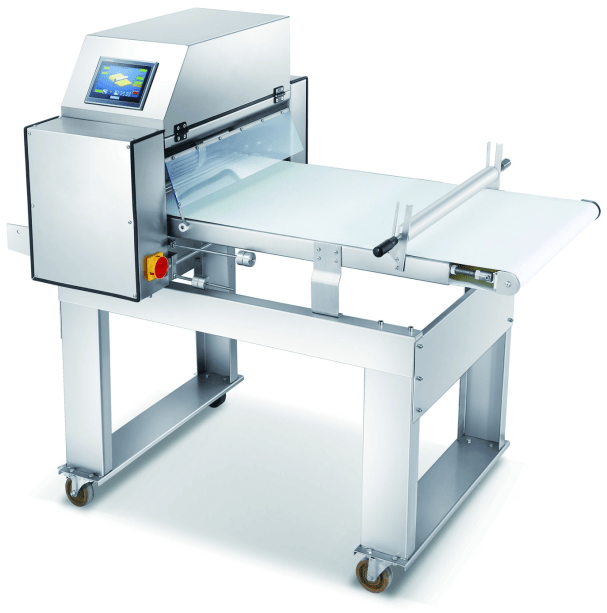

Q800Z Automatic Dough sheeter

Flatten the dough: Automatically flatten the dough to make it thinner and more even. When making croissants, the dough is pressed into thin sheets for subsequent rolling.

Helps in processing the dough: Helps to automatically feed the prepared dough into the machine, flatten it and then output it. When making croissants, you need to roll them multiple times, and the step of thinning the dough is critical.

Maintains Dough Shape: An automatic dough sheeter keeps dough at a consistent thickness and shape. In croissant making, maintaining the consistency of the dough greatly affects the appearance and texture of the croissant.

Function:

The PLC automatic control system fully automatically controls the descent of the pressure roller and automatically changes the reciprocating direction of the pressure surface. The program can store 99 different formulas.

The automatic powdering function automatically controls the amount and time of powdering, and also has an automatic dough rolling function.

The automatic reversing upgrade is designed with clutch control, which is more durable than traditional reversing and has almost zero failure rate.

The thickness of the pressing surface is uniform, and the precision grinding roller and high-frequency chrome plating ensure that the pressing roller will never rust.

Food grade conveyor belt, easy to clean.

JP-630 Average Dough sheet leveling machine

Ensure uniform dough thickness: After sheeting, the dough may have uneven thickness. The average dough leveler can level the dough to ensure that the thickness of the dough remains consistent, so that the final croissant has a beautiful shape and Even mouthfeel.

Improve production efficiency: The automated operation of the average dough leveling machine can greatly improve the production efficiency and ensure the quality and consistency of mass-produced dough. This is especially important in factories that produce croissants on a large scale.

Function:

Used in conjunction with a cutting machine, the production speed automatically matches the back-end cutting machine.

NK600 Sharp Machine

Function:

PLC touch screen automatic control system, fully automatic control of the conveyor belt, automatic control of vertical cutter speed. It has an edge trimming function and can store 99 different recipes. It uses a stainless steel body and a food-grade PU strap.

CJ200 Croissant Machine

The croissant bread machine can automatically roll the dough into a croissant shape to ensure a consistent shape. This kind of machinery can greatly improve production efficiency, especially when large quantities of croissants need to be produced, saving a lot of labor and time costs. Automated croissant machines can reduce human errors, making bread making smoother and reducing labor intensity.

Function:

The production speed is adjustable, the tightness of the trumpet roller is adjustable, and various specifications and sizes can be rolled. And additional gear functions can be added as needed.

P600 Automatic conveyor

It is used to transport food raw materials such as plates and dough, and can be used in conjunction with other production equipment.

Function:

The PLC touch screen automatic control system fully automatically controls the conveyor belt and plate placement, which can achieve perfect transition of triangular surfaces without deviation. Stainless steel body, food grade PU belt.

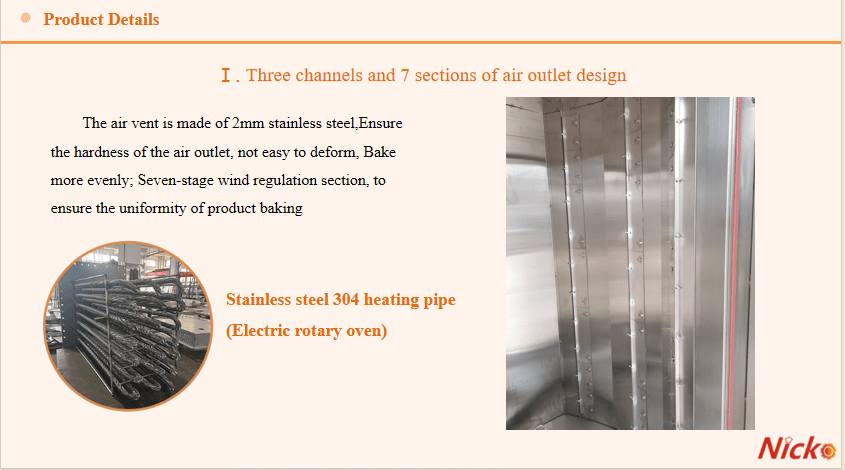

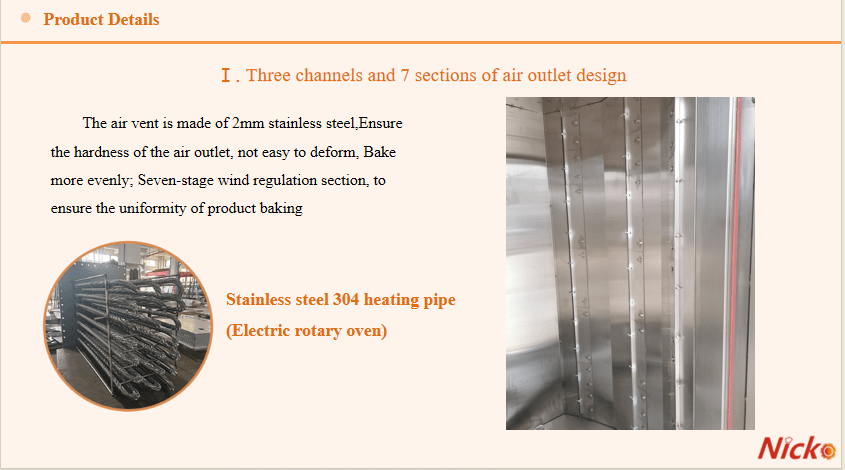

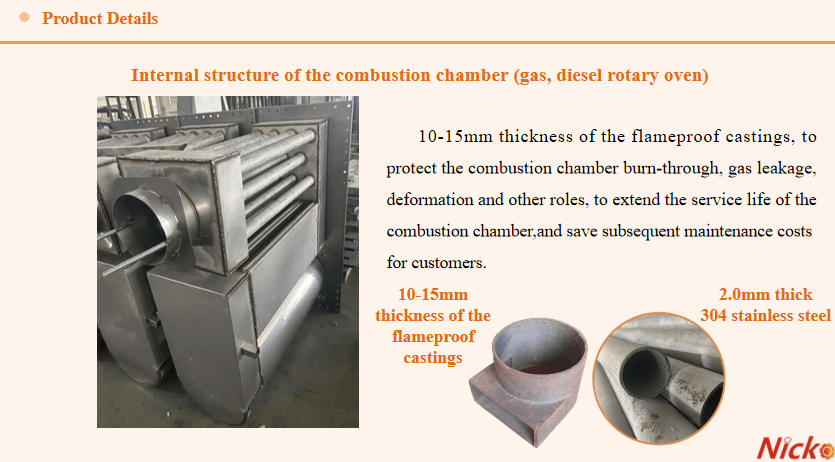

T-64G Gas Rotary Oven

In the process of making croissants, the rolled and shaped dough needs to go through steps of fermentation and baking. At this time, the gas rotary oven comes in handy.

The gas rotary oven can provide uniform high temperature, making the dough quickly expand, become soft and golden and crispy during baking.

This oven can quickly reach the required high temperature, and through the rotation function, the dough is heated more evenly, the croissants are heated evenly, and the finished bread tastes better.

More equipments

Mixer: https://www.nicko.com.cn/products/mixer/

Dough sheeter : https://www.nicko.com.cn/products/dough-sheeter/

Chiller cabinet: https://www.nicko.com.cn/products/chiller/

Bread proofer: https://www.nicko.com.cn/products/proofer/

Contact us:https://www.nicko.com.cn/contact-us/