Croissant has a long history and is now loved by many gourmets.

It is said that the history of croissants can be traced back to Austria in the 17th century. At that time, Austria had a kind of bread called Kipferl, which was the earliest form of croissants.

Later, croissants spread to France, and after improvements by local bakers, they gradually evolved into the French croissants we know today. From the end of the 19th century to the beginning of the 20th century, croissants gradually became a classic food on the French breakfast table. Later, they spread to all over the world and became a representative of French cuisine.

Croissants that everyone loves

The appearance of the croissant is very distinctive, and it looks delicious.

There are layers of pastry on the outside of the croissant. The outer skin is golden and crispy, and the inside is soft and sweet. Its production process requires multiple folding, rolling, fermentation and baking processes. The process is relatively complicated to achieve the ideal bread effect. . The elegance and complexity of the production process of this kind of cuisine are also consistent with the characteristics of French cuisine: they would rather spend a lot of time to produce exquisite and elegant cuisine.

People’s pursuit of food is constantly changing. Over time, people have made many changes to the taste and shape of croissants, and people’s “croissant recipes” have become more abundant, such as chocolate croissants, cream croissants, and even people will make croissants similar to Hamburgers are a new kind of delicacy that whet your appetite.

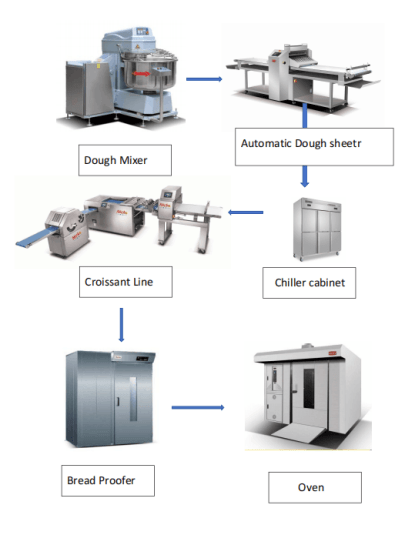

How to make croissants in batches? Process and Equipment List

People like to eat croissants so much. If you are planning to open a food factory or bakery specializing in the production of croissants, then the recommended equipment list for the following process may be what you need to consider.

Part 1: Preparation

- Prepare the proportion of ingredients and prepare flour, yeast, sugar, salt, butter and other raw materials. Before starting to make croissants, the chef needs to have many years of baking experience, be familiar with the croissant process, and receive professional training.

2. Prepare equipment such as large dough mixer, Dough fermentation equipment and workbench. These equipment require a certain area of production space, and these equipment should meet hygienic standards, have certain intelligence and automation, be efficient and achieve your baking results.

Equipment recommendations: Nicko croissant production line

As the world’s most professional baking manufacturer, nicko provides professional croissant line equipment to meet your one-stop service for making croissants. After years of verification, nicko’s baking equipment has achieved success for thousands of customers around the world.

Representative equipment includes: 800Z automatic dough sheeting machine, JP-630 average dough leveling machine, NK600 sharpening machine, CJ200 croissant machine, P600 automatic conveyor, T-64G gas rotary oven etc., with high degree of automation and high production speed. Fast, reliable quality, currently purchased by a large number of customers around the world.

For more information about Nicko Baking’s honorary qualifications and customer cases, please click: https://www.nicko.com.cn/about-us/

Part 2: Production Process

1. Dough making

Put the raw materials into the dough mixer in proportion, and complete the mixing process through automated equipment.

To ensure efficient work, the equipment you use should have a powerful motor that can consistently mix large amounts of dough. And there are multiple mix speeds and timer functions to ensure your production standards are followed to the letter.

Recommended equipment: nicko Spiral Mixer

Link: https://www.nicko.com.cn/products/mixer/spiral-mixer/

- Dough forming

After the dough is fully mixed, the dough needs to be divided into small pieces by an automatic forming machine for use in the production line.

Recommended equipment: Nicko’s Dough Sheeter

Equipment Benefits: A dough press can flatten large pieces of dough faster than rolling dough by hand. Furthermore, since it allows precise control over the thickness and shape of the dough.

Link: https://www.nicko.com.cn/product/dough-sheeter/

- Filling processing

Since there are many types of croissants, fillings of different flavors can be prepared according to your customer’s needs, such as chocolate filling, fruit filling, etc.

- Automatic production line

The automatic production line is used to complete the steps of shaping, filling, fermentation and baking of the croissant.

Partial equipment list introduction:

P600 automatic conveyor: PLC touch screen automatic control system, fully automatic control of the conveyor belt, automatic control of plate placement, able to achieve perfect transition of triangular surfaces without deviation.

800Z automatic dough sheeting machine: PLC automatic control system, fully automatic control of the lowering of the pressing roller, automatic change of the reciprocating direction of the pressing surface, the program can store 99 different formulas, and is equipped with automatic flouring function and automatic rolling function.

NK600 sharpening machine: It has a touch screen automatic control system, fully automatic control of the conveyor belt, and automatic control of the vertical cutter speed.

P600 automatic conveyor: It has a PLC touch screen automatic control system, fully automatic control of the conveyor belt, and automatic control of plate placement.

5.Baking process

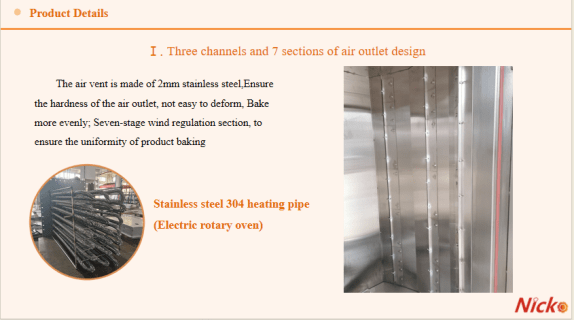

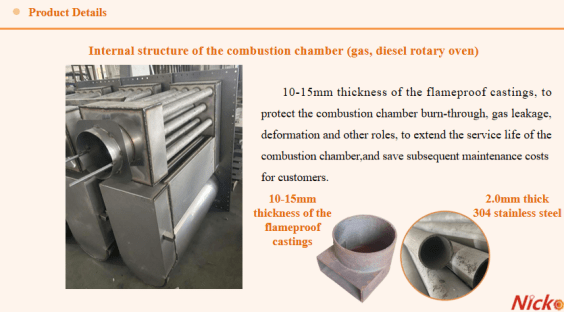

This is the most important step in baking croissants. After the previous process is completed, the formed croissants need to be sent to a large oven for baking. The oven is required to heat quickly, heat evenly, and accurately control the baking time.

Equipment recommendation: T-64G gas rotary oven

In the process of making croissants, it is recommended to use the T-64G gas rotary oven. It provides evenly high temperatures that allow the dough to expand quickly during baking, making it soft and golden and crispy on the outside. The croissants heat evenly and taste better.

6.Cooling and packaging

After the baked croissants are cooled, the food factory can package and label them, and prepare them for packaging and marketing.

Part3: Quality Control

1. Regularly clean and maintain production equipment to keep the production environment clean and germ-free. To reduce maintenance costs, you should choose baking equipment made of stainless steel, as this material is less likely to breed bacteria and is easier to clean and maintain.

2. Strictly control the quality of raw materials, so you need to cooperate with reputable raw material suppliers in advance. The cooperation should be as stable as possible and look for well-known brands, so that you can focus more on baking croissants.

3. It is also important to randomly inspect the finished products to ensure that the croissants meet hygienic standards, and only in this way can you truly feel the delicious taste.