Croissants, also known as thousand-layer bread, originated in France. It is made of layers of dough and butter, and is known for its crispy texture, distinct layers, and crescent-shaped shape.

It is said that there is an interesting legend about croissants. In 1683, the Ottoman army besieged Vienna, resulting in a shortage of food in the city. The chefs in the city used the remaining flour and butter to make a special bread that was shaped like the logo of the Ottoman army.

When Vienna successfully resisted the siege, the bread was named “Kipferl” (German for horns), and later evolved into “Croissant”. Although this is just a legend, it has added some mystery to croissants.

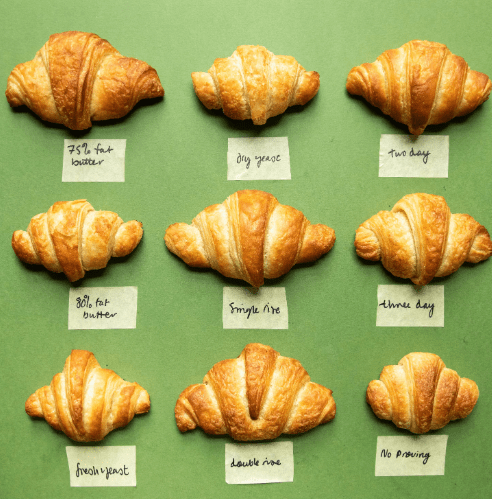

Features of croissants

First of all, when making croissants, the dough must be folded, flattened, and buttered many times to produce a multi-layered taste. Moreover, due to the high butter content in croissants, the butter evaporates during baking, and the bread is golden and crispy on the surface and soft on the inside. The air mixed in the folded layers of croissants makes it soft and has a hint of sweetness.

In addition to the traditional original croissants, people have also invented various variants of croissants with various fillings, such as chocolate croissants, dried fruit croissants, cheese croissants, etc., which have richer flavors.

About the commercial production of croissants

Unlike handmade croissants at home, the commercial production of croissants is very different. Which method do you prefer?

First of all, the commercial production of croissants requires large-scale machine production, such as a croissant production line. This production line consists of multiple automated equipment to form a complete production process, which can make it easier to make dough in large quantities, and automatically complete the stacking and forming steps, and can produce high-quality croissants at a lower cost, increasing profit margins. However, making croissants at home requires a lot of time and manpower to make them manually, and the number of breads made at one time is also small, which cannot reduce the average cost.

Moreover, commercially produced croissants are highly standardized, requiring a high degree of consistency in weight, shape, taste and baking degree, so that each bread is basically the same in taste and appearance. Croissants made in home workshops are difficult to achieve this, and the quality cannot be fully automatically controlled.

Although home-made croissants are easier to customize, with the development of science and technology, the croissant production line produced by Nicko, the most professional baking manufacturer at present, uses more advanced automated manufacturing technology, which can make different types of croissants through different recipes to meet the different taste needs of consumers.

Process of commercial production of croissants

1. Croissant recipe development

Common croissant recipes and development methods:

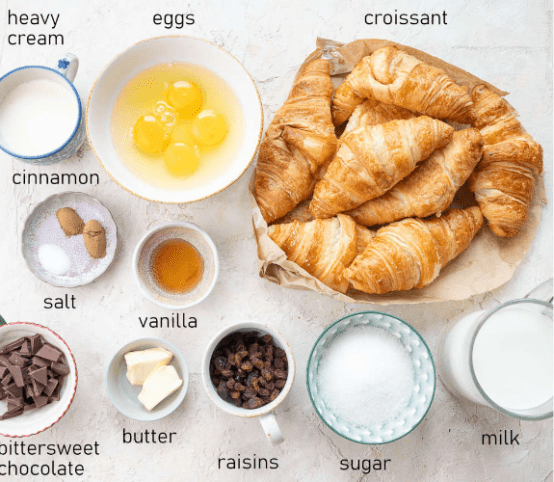

Original croissant: The dough of the original croissant contains flour, butter, sugar, yeast, salt and other raw materials. During the fermentation process, be patient and wait for the dough to expand, and pay attention to the temperature control during baking

Chocolate croissant: Add chocolate chips or chocolate sauce to the dough.

Cream nut croissant: Add cream and various nuts, such as almonds, walnuts, etc., to the dough of the original croissant.

Fruit croissant: Add dried or fresh fruits, such as raisins, blueberries, etc., to the dough.

2. Procurement of raw materials for croissants

Choose high-quality high-gluten flour, unsalted butter, active dry yeast, and then purchase the right amount of sugar and salt. If milk powder is to be added to the formula, fresh and high-quality dairy products must be selected.

When purchasing raw materials, choose reputable merchants to ensure food safety, and carefully check the shelf life to avoid using expired raw materials. If you are producing croissants industrially, please sign a long-term supplier contract with a regular manufacturer, which is more legally guaranteed and allows you to focus on producing bread and improving the quality and taste of croissants.

3. Purchase professional croissant production equipment

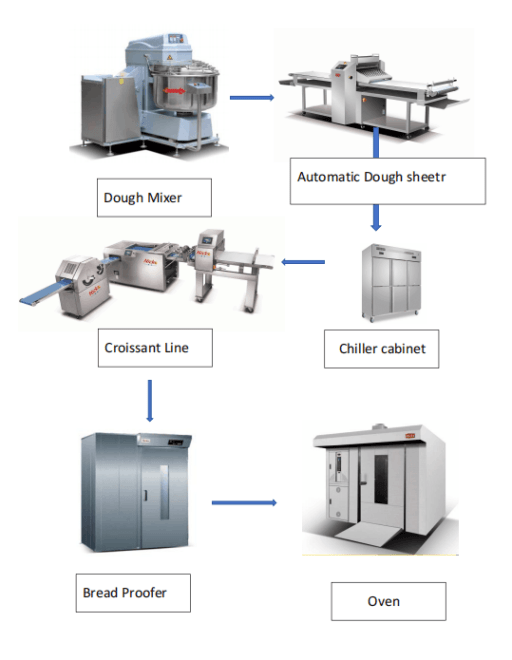

Commercial production of croissants requires professional equipment, including but not limited to dough mixers, dough rollers, ovens, etc.

Take nicko, the world’s most professional baking manufacturer, as an example. The croissant line it provides is fully equipped, and croissants can be mass-produced in a highly automated manner using one set of equipment.

Nicko’s available production line equipment includes: 800Z automatic dough sheeting machine, JP-630 average dough sheeting machine, NK600 sharp machine, CJ200 croissant machine, P600 automatic conveyor, T-64G gas rotary oven, etc., with reliable quality.

Welcome to consult nicko’s professional sales manager. Please inform us of your equipment requirements and we will provide you with professional croissant wire equipment recommendations: https://www.nicko.com.cn/contact-us/

The automatic production line is used to complete the steps of shaping, filling, fermentation and baking of the croissant.

4. Production process optimization

Since croissants are commercially manufactured, many people need to work together, so an efficient production process must be developed, including a production flow chart, and each process is managed by a dedicated person to achieve the highest production efficiency. At the same time, process management ensures product quality because it implements personal responsibility.

5. Croissant packaging and marketing

Design packaging according to your customer base, such as inviting models to be your image spokesperson, determine the color, logo and packaging design according to your brand image, and develop marketing strategies to promote your croissants.

6. Quality control of croissants

Establish strict quality control standards and regularly check the quality of croissants. Common inspection contents include but are not limited to: checking color and shape, and regularly testing fluffiness, sweetness, and saltiness.

7. Sales channels

Establish sales channels for various croissants, such as offline supermarkets, bakeries, restaurants, and online e-commerce platforms.

We recommend you to buy the croissant commercial production equipment of Guangzhou Nicko Machinery Co., Ltd., which specializes in providing baking equipment for bakeries, Western-style chain stores, coffee shops, food factories, and supermarkets. With more than 20 years of industry experience, we have served 2,500 customers and 100% quality assurance.

For more honors and customer cases about Nicko Baking, please click: