How to open a bakery? After you have spent a lot of time completing market research and a detailed business plan, the next step is to raise funds, select a location (choose a place with large traffic and near a crowd gathering area) and register a company, and finally start purchasing professional bakery equipment.

What are the Essential equipment for opening a bakery? Since the bakery itself is limited in space and the initial capital investment is relatively large, it is necessary to give priority to purchasing necessary early bakery equipment.

To purchase bakery equipment, you need to start from business needs and make a list of equipment that must be purchased first to avoid buying inappropriate tools that take up too much space and waste equipment.

Nicko baking equipment experts have listed several recommended equipment lists, hoping to help you succeed in your business. Next, you may need the following bakery equipment list: 10 essential equipment for opening a bakery (with equipment recommendations).

10 Essential Equipment for Opening a Bakery

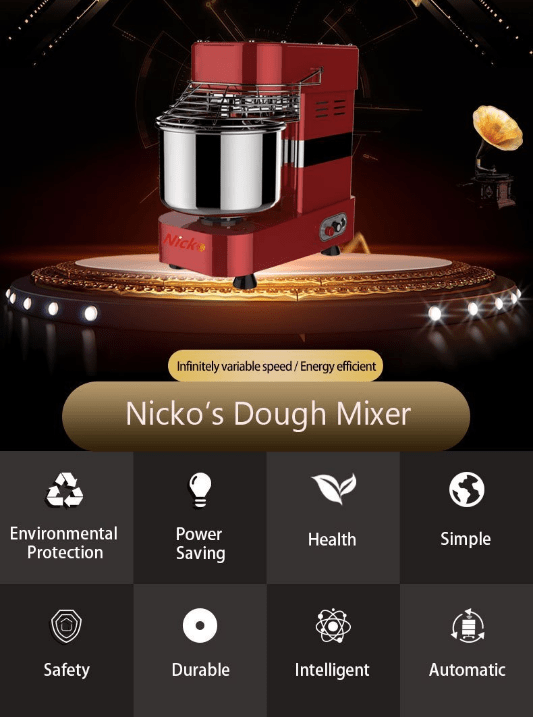

Commercial mixer for bakery

Dough is the basis for making delicious bread. In a bakery, if bread raw materials are mixed manually, not only is the workload huge, but also the dough cannot be evenly mixed, and the quality and taste of the bread cannot be guaranteed. Therefore, the use of high-efficiency dough mixers has become a essential equipment for bakeries.

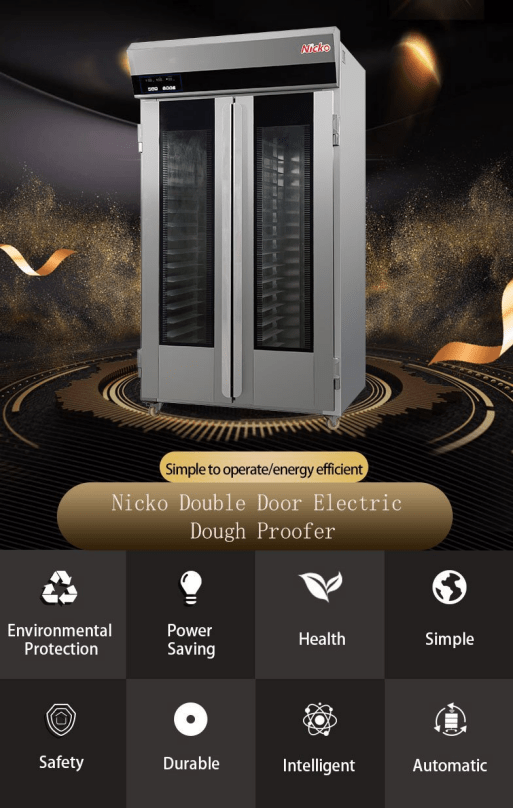

Dough Proofer

In a relatively backward era, bread chefs used traditional fermentation methods, which seemed to be more “delicious”, but you could not accurately control the quality of this bread – the uniformity and taste of the same traditional fermentation may be very different, which will hinder your bakery from forming a stable word-of-mouth effect.

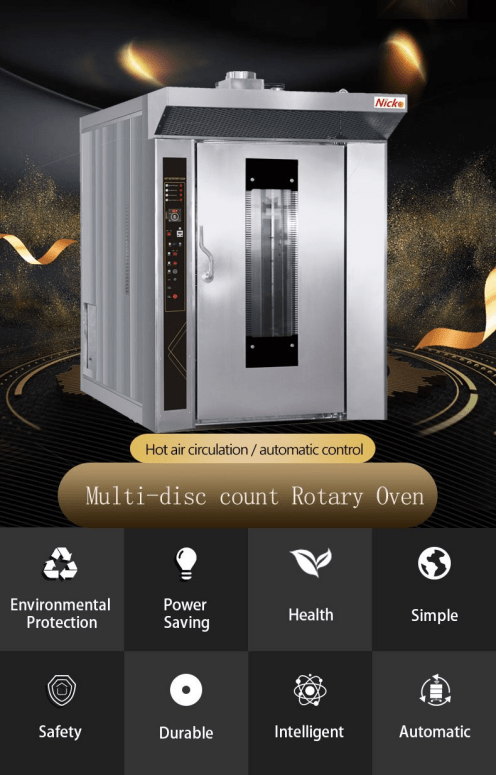

Commercial bread oven

The Commercial oven can be said to be the most important equipment in the bakery. No matter how good the chef is, if he does not use a professional commercial oven, it will be difficult to bake products with stable quality, and it will not be possible to create profits through stable commercial scale.

Using unprofessional or low-quality bread ovens has many adverse consequences for the bakery, such as: unstable bread quality or large taste differences, low production efficiency, increased costs, and even the production of food that does not meet hygiene standards, which seriously threatens your business development.

When baking bread, commercial ovens are very important, which can bake dough into rich foods such as bread, rolls, and rusks. Using a professional bakery oven, it can provide a constant temperature and a scientific heating method, which can bake bread with uniform color and delicious taste. Through precise heating control equipment, chefs can accurately control baking temperature, humidity and time, and can directly observe the baking process, so that the color and quality of the bread crust are stable, and the quality of the bread can reach the desired effect. Moreover, professional ovens have high production efficiency, not only because of their high thermal efficiency, but also because of their large capacity, which can bake at the same time, and can easily cope with the peak of purchases and meet the needs of large-volume orders. Don’t miss the commercialization opportunity.

Therefore, for your long-term development, Nicko recommends that you buy a professional commercial oven. Bakery oven recommendation:

Bakery workbench

The bakery workbench is crucial to the efficiency of the baker. It is not only easy to clean, but also carefully designed to facilitate teamwork and improve efficiency. As the place where bakers use to mix, knead and shape dough, bakers will process dough on the workbench (such as making bread, rolls and crusts), cut it into the required shape and quantity, or create some unique pastry shapes, decorate the surface, and give full play to the chef’s creativity.

In addition, bakers need to clean and disinfect the workbench frequently, so it is generally recommended to use stainless steel materials, which are easier to clean, meet food safety and hygiene standards, and avoid risks to public food safety.

Bakery Refrigeration Equipment

Generally speaking, bakery refrigeration equipment is often used to store ingredients to ensure the freshness of ingredients in case of emergency, such as flour, butter, yeast, etc. Some bread and pastries need to be kept under refrigerated conditions, such as chocolate and cream. If your site is large enough, you can also equip it with a dedicated dough fermentation temperature control device to control the dough fermentation speed.

Bakery Slicer

Slicers are generally used to quickly cut bread into neat slices to improve production efficiency. Because it is a precision mechanical control, it is more accurate than manual slicing, and the cuts are neater, which not only makes the bread look much more beautiful, but also ensures that the customer gets the same amount. It greatly reduces labor costs and allows bakers to spend more time on more important processes. Another key point is: using a slicer to reduce the risk of injury and food hygiene problems caused by manual cutting will be healthier.

Packaging Equipment

We all know that bakeries need to conduct commercial marketing. But before marketing, you need to package your product well, such as using exquisitely designed packaging that reflects your brand characteristics. In order to make your bread more attractive, it is necessary to use professional bakery packaging equipment.

In addition to being more beautiful, using professional bakery packaging equipment can extend the shelf life of food, and can also identify the name, ingredients and nutritional information, reduce losses during transportation and display, and make it more convenient for customers to carry and more convenient for customers.

Precision weighing equipment (Weighing Scales)

Precision weighing equipment is used to accurately measure ingredients and raw materials, which is the basis for ensuring consistent bread quality. With professional precision weighing equipment, you can accurately mix ingredients, reduce errors, control costs and improve food safety (avoid food safety problems caused by excessive or insufficient ingredients), and reduce cross-contamination in the bakery production process.

Bakery display cabinet (Display Case)

Display cabinets can directly display freshly baked bread, cakes, desserts and pastries and other products to help customers choose delicious food. In addition, we cannot ignore the role of display cabinets in keeping food fresh, and they need to have insulation or refrigeration functions.

In addition to purchasing professional display cabinets, it is recommended that you use the display cabinets reasonably to reduce the pollution of the external environment to the products.

Cleaning Equipment

Choose bakery cleaning equipment according to your actual needs. For example, bakery-specific cleaners, vacuum cleaners, steam cleaners, dishwashers, wet mops and cleaning cloths, steam cleaning stoves, etc.